Composite Board Testing

Third Party Testing Of AeroTek & Competitor Boards

AeroTek composite board give you the best value for your money. Not only are our boards the most affordable, but they are the highest rated in strength and reliability. You don’t have to take our word for it, check out these third-party test results.

Test Certifications:

- ESTM E-84 approved

- FMVSS 302 / CMVSS 302

- Zero Formaldehyde or any other toxic chemicals

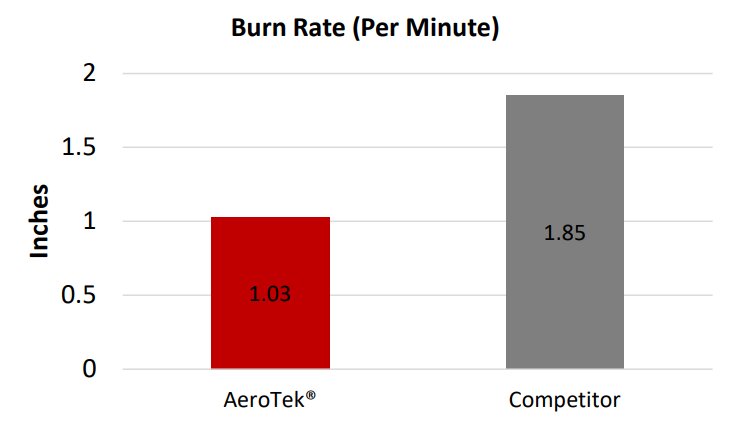

Burn Rate:

Sample description: AeroTek® Composite Board material with an average measured thickness of .115″

AeroTek® (1.03″/min)

Azdel Onboard (1.85″/min)

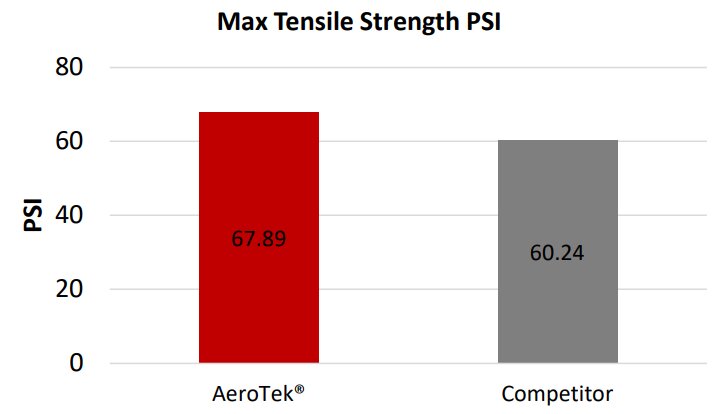

Tensile Strength:

Objective: To evaluate the performance and bond strength of panels before and after accelerated aging cycle

Procedure: 3rd party testing service received eight sets of 2-inch by 2-inch cut-out samples. The samples were construed with RV64021 and the following materials:

MT1 A-E Azdel Onboard composite; Ambient FWT (Max Tensile Strength) – 60.24

MT2 A-E AeroTek® composite; Ambient FWT (Max Tensile Strength) – 67.89

MT5 A-E Azdel Onboard composite; Thermal Cycled + FWT (Max Tensile Strength) – 53.57

MT6 A-E AeroTek® composite; Thermal Cycled + FWT (Max Tensile Strength) – 70.60

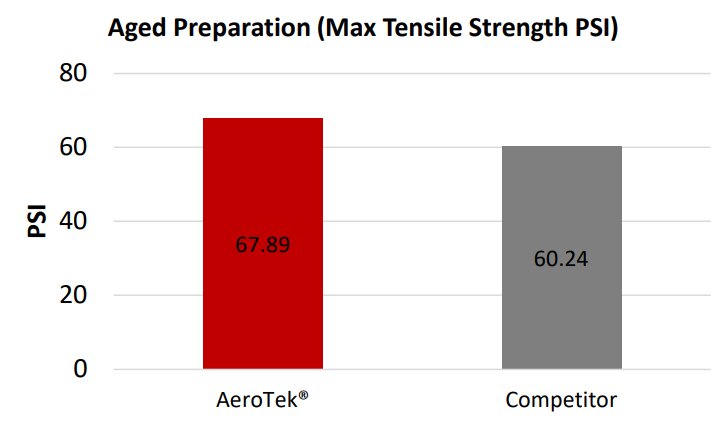

Aged Preparation:

Samples MT5 and MT6 were placed into accelerated aging cycle

The parameters for the aging test were as follows:

1) 10 hours at 180°F and 10% Relative Humidity (RH)

2) 2 hours transition to next setting

3) 10 hours at -40°F and 0% RH

4) 2 hours transition to next setting)

5) 10 hours at 100°F and 90% RH

6) 2 hours transition back to 1) setting

The six-step cyclic testing described above was repeated for five cycles. The total time for the aging process was 7.5 days.

*Tensile Strength

Bond strength analysis was performed using a model # 5984 Instron with a 30,000 lb load cell at a speed of 0.5 in/minute. Five samples for each aged were tested. Prior to adhesion to aluminum T-bar, each sample was lightly sanded on both sides and wiped clean with Isopropyl Alcohol (IPA). Each sample was adhered to an aluminum T-bar on both sides using an epoxy and allowed to cure overnight. They were then tested for tensile strength at room temperature.